Our customers have need of large numbers of stamped parts, produced with extreme repeatability. This enables them to update their production processes to high standards.

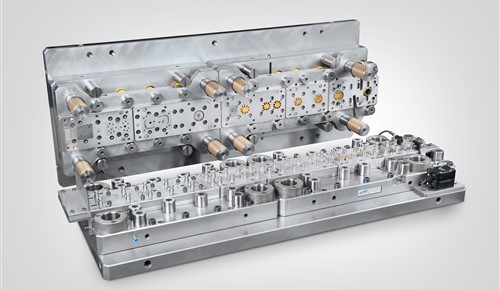

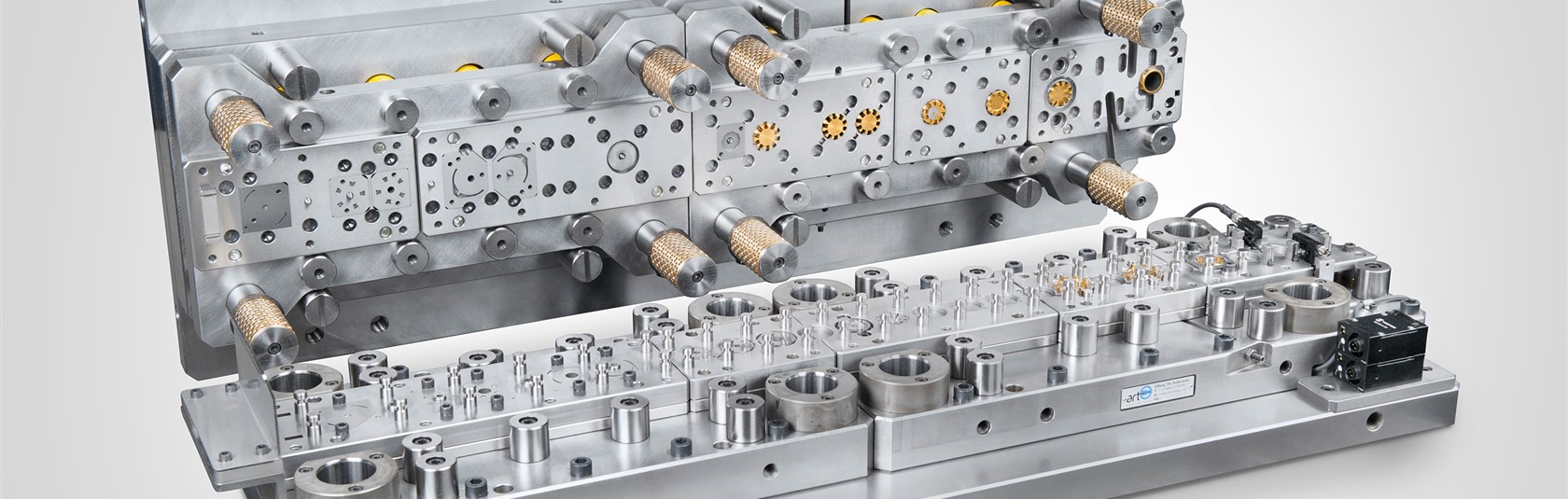

Transforming sheet metal strip to complete end products, processed in a progressive stamping tool is our drive. From 1-out tools, producing about 6.000 parts per hour to 27-out stamping dies for 880.000 parts per hour.

Whether it concerns deep drawn wick sustainers for the candle light industry (for about 24 billion candles a year, meaning about 200.000 candles burn at every moment of the day), or stamped chain elements for saw-chains (for about 80.000 kilometer a year) or 100 million elements for the CVT-push belt, we supply our customers with turn key stamping processes.

A team of skilled specialists, equipped with modern production machines in a fully climatized environment, is ready to meet your demands. Meeting full customer satisfaction by engineering, manufacturing, assembling and validating is the challenge we accept time after time.

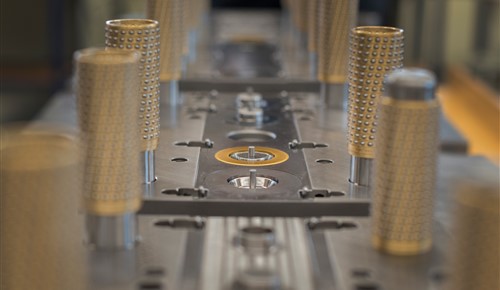

Our tools can be equipped with full carbide stamping and forming components, full sets of process monitoring sensors, exchangeable modules to increase the overall equipment efficiency (OEE) and full spare part kit.

Our dedicated team is ready for the next challenge!